If you have been in the car industry for a while, then you may have come across CVT under the transmission column of a spec chart while doing online research for your next new car, or just learning about your car in general. But what is this ‘CVT’, and how does it work? What exactly does it do for a car, and what are its benefits and disadvantages?

“CVT” stands for continuously variable transmission. Other names for a CVT include shiftless transmission, stepless transmission, or pulley transmission. CVT is a type of transmission that uses pulleys rather than gears to carry power from the engine to the drive wheels. It can promote fuel efficiency by allowing an engine to run at lower revs, like when traveling on a highway, or by keeping the engine running at the top of its power band when more oomph is required.

How does CVT work?

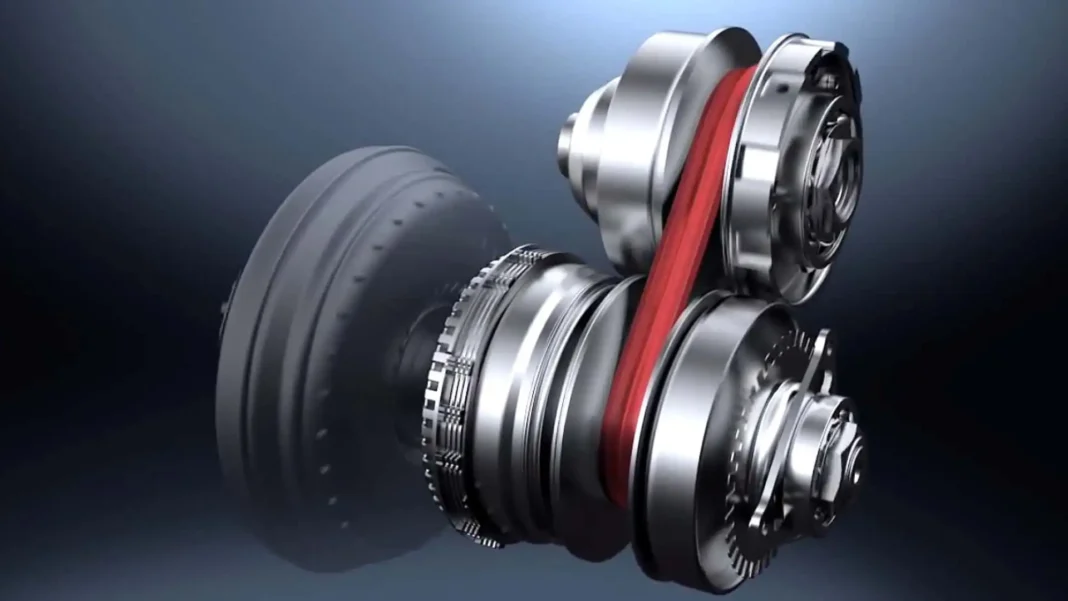

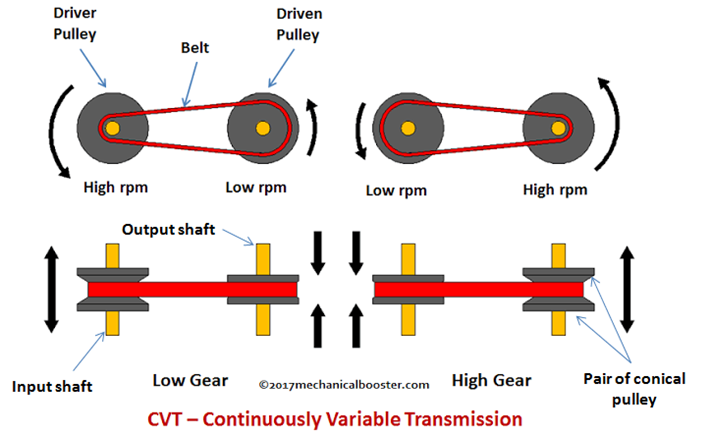

CVTs utilize hydraulic pressure, spring tension, or centrifugal force to move two pulleys, the driving “input” pulley and the driven “output” pulley. The driving pulley, which is attached to the engine’s crankshaft, is responsible for transferring engine energy to the transmission. The driven pulley, also known as the output pulley, distributes energy to the driveshaft.

On each pulley, a belt travels in a groove between two cones. As the pulley’s diameter grows, the belt rides lower in the groove, and the radius of the belt loop decreases. The pitch radius determines the gear ratio, with one pulley’s range increasing while the other’s decreases. The varying radii of the pulleys create an infinite variety of gear ratios, from low to high.

Going back in time

Leonardo da Vinci is recognized for having created the earliest CVT design. Considering that cars had not yet been created, he most likely did not imagine its application in a vehicle. But Karl Benz, the father of the modern automobile, did take up the cause and employ a type of belt-driven CVT in the Patent Motorwagen.

Benz Patent-Motorwagen, the First modern automobile

Although the CVT was well-liked in the powersports business (think side-by-sides and snowmobiles), it wasn’t until the late 1980s that it began to take off in the automotive industry, with Subaru setting the standard. As the longevity of the technology has increased since then, other automakers have dabbled in this area.

Pros

Less weight

Although this isn’t always the case, CVT transmissions are usually smaller and lighter than traditional automatic transmissions. Compared to their conventional counterparts, CVTs weigh less and take up significantly less space.

Enhanced fuel efficiency

In contrast to conventional automatics, the CVT has the ability to permanently alter the gear ratio in order to keep the engine operating at its best. In general, a conventional automatic transmission optimizes engine power better the more gears it offers. The CVT offers an endless number of combinations that result in far higher gas economy than even the most sophisticated conventional transmissions, which only have ten gears.

Seamless long-distance drives

With the use of a belt-driven system, the CVT rotates the rotor disc or pulley inside the unit in response to the vehicle’s power and momentum input. There are no abrupt lurches or jerks, unlike when you drive a car with a manual transmission, and the system sounds wonderfully smooth but is actually very subtle.

As a result, CVT improves your drive’s quality and sophistication. This is particularly noticeable when driving long distances, when your car’s engine is entirely relaxed and calm.

Fewer parts and lighter weight

Because the CVT streamlines the entire shifting process, fewer parts are needed to produce CVT. Because there are fewer parts, there is also a lower likelihood of mechanical failure. This can therefore be quite beneficial in the long run.

Additionally, the engine weighs less because the CVT unit doesn’t need automobile gears to maintain the proper ratio. This also results in the engine’s size being reduced, which is fantastic. Additionally, as everyone is aware, one of the main benefits of a car with CVT is increased fuel efficiency, which is directly correlated with weight reduction.

Cons

High cost of maintenance and repair

The likelihood of a CVT failing is higher than that of a typical conventional transmission, according to the most notable incidents. The CVT has been seen to last between 80,000 and 90,000 kilometers. Following this, the CVT belt begins to deteriorate and wear out. As a result, automakers frequently replace the entire transmission system, which significantly raises repair costs.

Additionally, CVTs are still relatively new in the automotive industry, and there are fewer certified CVT specialists than there are automatic transmission specialists. Independent stores may raise their prices if they lack certified CVT technicians. For a customized quotation on the transmission in your car, be sure to ask your service consultant.

Unpleasant acceleration sound

If you’ve ever driven a car with a CVT, you’ll notice that there’s a strange noise when you accelerate. The rubber band effect is the term for this. The power delivery may not be significantly impacted by the CVT unit’s belt contraction and expansion. However, compared to other broadcasts, it produces some non-linear accelerating sound.

Do you need to get a CVT?

Purchasing a car is a significant financial commitment that requires thorough research. You can choose a car with a CVT if you believe you can manage it. Before you decide to purchase a car with one, it is advised that you take a comprehensive test drive. It’s also critical to remember that some automakers have experienced problems with their CVT reliability.